Bob Zybach and I went on a field trip to the Rim Fire. The first stop on the tour showed us the Sierra Pacific Industries’ salvage logging results. I’m posting a medium resolution panorama so, if you click on the picture, you can view it in its full size. You can see the planted surviving giant sequoias on their land which were left in place. You can also see some smaller diameter trees, bundled up on the hill, which turned out to be not mechantable as sawlogs. You might also notice the subsoiler ripping, meant to break up the hydrophobic layer. They appear to have done their homework on this practice, and it is surprising to see them spending money to do this. SPI says that their salvage logging is nearly complete, and that they will replant most of their 20,000 acre chunk next spring. They have to order and grow more stock to finish in 2016.

Wood

Australia’s First CLT Public Building

Thanks to Forest Business Network for this one..

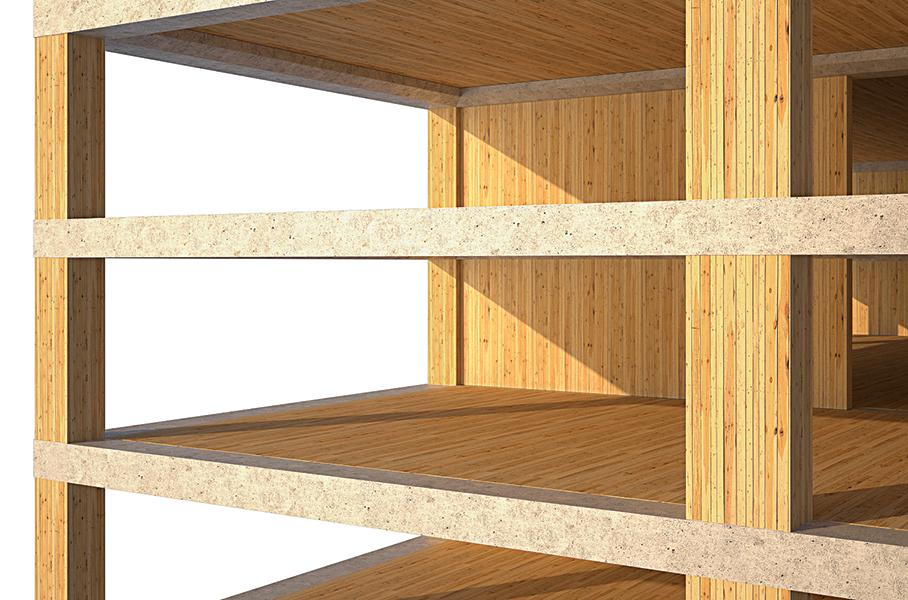

Australia’s first public building made from cross-laminated timber (CLT) has opened its doors. The Library at the Dock in Melbourne was built in partnership between the City of Melbourne, Places Victoria and Lend Lease. The major structural components of the three-storey library are made from more than 500m³ of CLT, produced at Stora Enso’s Ybbs and Bad St Leonhard units in Austria.

One of the main advantages of building with wood is the construction time: the building structure was completed in two-and-a-half months.

“The Australian construction industry is well used to working with wood, and CLT has recently been gaining a lot of attention from construction companies due to its many advantages. The Library at the Dock is an excellent example of how wood, and especially CLT, can deliver added value as a construction material,” said Matti Mikkola, vice-president, Building Solutions, Stora Enso Building and Living.

The Library at the Dock stands on a wharf originally designed in 1879. CLT’s light weight meant only a limited number of additional pilings and repairs of the old timber posts were required.

In addition to CLT’s speed and weight advantages, it also has strong environmental credentials.

“CLT offers a sustainable alternative to conventional materials, given its potential to be carbon negative,” said Andrew Nieland, head of timber solutions for Lend Lease. “CLT is a lightweight, strong, solid wood and, given its prefabricated nature, drives efficiency improvements onsite.”

The Library at the Dock achieved a 6 Star Green Star rating from the Green Building Council of Australia.

Melbourne is already home to the world’s tallest CLT residential building. The 10-storey Forté Tower, also in the Docklands area, opened last year.

So does anyone out there know why Austria had to provide the CLT? There are no producers anywhere in Australia? Why is that- patents? Investment requirements?

Wisconsin Researchers Test Affordable Wooden Shelters

The weather these last couple of days has made me tornado-sensitive, and I ran across this story from the Insurance Journal (through a link from Forest Business Network). Here’s the link and below are some excerpts. Note Robert Bonnie’s statement at the end.

Bob Falk is frugal and a realist.

The research engineer at Forest Products Laboratory in Madison, Wis. could have used expensive lumber, pricey nails and high-grade plywood in his tests to create an almost impenetrable tornado shelter made of wood. But that would have missed the point.

That’s why Falk and his team of engineers have been using an air cannon to fire, at 100 mph, 12-foot long, 15-pound southern pine 2-by-4s into specially designed walls made of some of the cheapest wood available.

The cannon mimics the forces of an F5 tornado with 250-mph winds. The lumber used to make the walls of the shelter is of such low quality, Falk had to specially order it because he couldn’t find it at area lumber yards or hardware stores.

“This is quite a resilient design,” Falk said after a test shot. “All we’re trying to do is absorb the energy.”

stormThe goal is to create an economical wood-based shelter that can be easily constructed in a basement or garage by anyone halfway skilled with a hammer and saw. The process for making a tornado safe room could be similar to that of building a storage shed that comes in a kit.

“You buy the lumber, you take it home, you put it together,” Falk told the Wisconsin State Journal. “And that’s an important aspect. Most safe rooms you can only put into new (homes).”

And the cost can be prohibitive for many. A basic safe room can easily cost between $6,000 and $15,000. Some are designed to be installed under the concrete slab of a garage while others are buried in a backyard. Exterior safe rooms, whether above or below ground, also pose a threat because users must go outside to access the shelter, Falk said.

The Forest Products Laboratory design costs between $3,000 and $4,000, can be bolted to the concrete floor of a basement or garage and consists of interlocking layers of low-grade board covered on the interior and exterior with plywood. The shelter has a steel door, which contributes about $1,500 to the cost, but Falk is working on plans for a wood door to further reduce the cost.

“The (low price) is another incentive for people to put one in their home,” Falk said. “It’s about the cost of a hot tub.”

Spring and summer in the Midwest and the South means tornado season. Last year, more than 30 people were killed in Oklahoma from a series of tornadoes. This year, 35 people have died, primarily in the South, from 74 confirmed tornadoes, including 15 in Arkansas.

Wisconsin is yet to experience a tornado this year, but in 2013 there were 16 documented tornadoes, resulting in no deaths and two injuries, according to the National Weather Service. The 30-year normal for the state is 23 tornadoes a year. Since 1844, the weather service reports that 511 people have been killed in Wisconsin tornadoes.

The state’s worst was in 1899 when 117 people died and 125 were injured in St. Croix County. But more people remember the F5 tornado that killed 9 people, injured 200 and caused $40 million in damage to the Iowa County village of Barneveld on June 8, 1984. The Stoughton tornado, in 2005, killed one person, sent three to the hospital and caused more than $45 million in damage to the city and surrounding towns.

Almost 15 months after the devastating storm, the town of Dunn in 2009 opened a $650,000 shelter with poured concrete tilt-up walls in the Bayview Heights neighborhood, home to 227 mobile homes. The above-ground shelter can hold 500 people and is also used as an emergency warming and cooling shelter and during severe thunderstorm warnings with high wind.

During the 2005 tornado, some residents drove into the storm in an attempt to reach the Stoughton Fire Department for shelter while others took refuge in nearby culverts.

“It’s taken 227 homes that were missing that one basic, very necessary safety feature and made them more safe,” said Cathy Hasslinger, the town’s clerk and treasurer. “The rural location there really made a shelter important.”

Falk’s design and research, which includes filming the tests with a high-speed camera, could have a similar impact. Demand is overwhelming the capacity of storm shelter builders in Oklahoma, The Associated Press reported. An affordable do-it-yourself model can only be a positive, said Robert Bonnie, U.S. Department of Agriculture’s undersecretary for natural resources and environment.

Bonnie was in Madison recently to tour the laboratory and watch Falk fire his cannon. Bonnie grew up on a farm outside of Louisville, Kentucky, and remembers cowering in the basement during one particularly bad storm in 1973 when he was 6 years old.

“For a long time I was actually pretty nervous about storms because of that,” Bonnie said. “This (FPL research) is critically important, not only for the direct use of providing safe shelters for people in tornadoes, but also, we need a vibrant wood products industry.”

This should be the link to some videos of the technology in Dropbox (if you like splinters, you’ll love this video) If you try it and it doesn’t work, let me know!

Also here’s some more information.

The World’s Most Advanced Building Material Is… Wood

Thought folks might be interested in this piece from Popular Science here.

Why the sudden interest in wood? Compared with steel or concrete, CLT, also known as mass timber, is cheaper, easier to assemble, and more fire resistant, thanks to the way wood chars. It’s also more sustainable. Wood is renewable like any crop, and it’s a carbon sink, sequestering the carbon dioxide it absorbed during growth even after it’s been turned into lumber. Waugh Thistleton estimates that the wood in Stadthaus stores 186 tons of carbon while the steel and concrete for a similar, conventionally built tower would have generated 137 tons of carbon dioxide during production. Wood nets a savings of 323 tons.

Demographers predict that the planet’s urban citizenry will double in 36 years, increasing the demand for ever-taller structures in ever-denser cities. Whether architects and construction firms build those towers from unsustainable materials like steel and concrete or employ new materials like CLT could make a huge difference in the Earth’s health. Put differently, the world’s urban future may just lie in its oldest building material.

…..

But the biggest driving force behind the turn toward wood is a growing awareness among architects and developers about their field’s contribution to climate change. “Our industry leads all others in terms of its impact on the planet and human health,” Waugh says. Concrete and steel require enormous amounts of energy to produce and transport, generating more than a ton of carbon dioxide per ton of steel or concrete.

Wood, on the other hand—even engineered wood like CLT, which requires additional energy to cut and press into sections—is far more environmentally friendly. According to Wood for Good, an organization that advocates for sustainable wood construction, a ton of bricks requires four times the amount of energy to produce as a ton of sawn softwood; concrete requires five times, steel 24 times, and aluminum 126 times. Wood also performs better: It is, for example, five times more insulative than concrete and 350 times more so than steel. That means less energy is needed to heat and cool a wood building.

When CLT is used to build high-rise towers, the carbon savings can be enormous. The 186 tons of carbon locked into Stadthaus are enough to offset 20 years of its daily operations, meaning that for the first two decades of its life, the building isn’t carbon neutral—it is actually carbon negative. Rather than producing greenhouse gases, Stadthaus is fighting them.

Power Fire 2014

We’ve seen pictures of the Power Fire, on the Eldorado National Forest, before. I worked on salvage sales until Chad Hanson won in the Ninth Circuit Court, with issues about the black-backed woodpecker. The court decided that the issue needed more analysis, as well as deciding that the Forest Service’s brand new mortality guidelines were “confusing”. From these pictures, it is very clear to see that those mortality guidelines were way more conservative than they maybe should have been.

As you can see, in this finished unit(s), there were ample snags available for birds to use, despite multiple cuttings, due to the increased bark beetle activity, during the logging. No one can say that they didn’t leave enough snags, (other than the Appeals Court). These pictures are very recent, shot last month.

This picture amused me, as I put this sign up back in 2005. Plastic signs last much longer than the old cardboard ones.

Here is another view of the area, chock full of snags, well beyond what the salvage plans asked for, to devote to woodpeckers and other organisms that use snags. People like Chad Hanson want more high-intensity wildfires, and more dead old growth. It is no wonder that the Sierra Club decided he was too radical, even for them.

Edit: Here is the link to a previous posting from almost 2 years ago, with pictures. https://forestpolicypub.com/2012/05/28/the-power-fire-six-years-later/

“Timber Trouble” in Wisconsin

Since Norman brought up Wisconsin, and I had seen this earlier, thought it would be a good time to post this.

Buried deep in Wisconsin’s northwoods is a story that warrants statewide attention.

In the coming days, the Gannett Wisconsin Media Investigative Team will bring you “Timber Trouble.”

Our three-part series focuses on the growing mistrust between the logging industry and the national forest service.

Gannett Wisconsin Media Investigative Team reporter Nick Penzenstadler and Post-Crescent Media photojournalist William Glasheen traveled north to do the reporting, photo and video work for the “Timber Troubles” project..

The Chequamegon-Nicolet National Forest and Laona area, in Forest County, serve as ground zero for our report.

Penzenstadler and Glasheen investigated whether the timber harvests inside northern Wisconsin’s national forest are being mismanaged. As a result of smaller harvests, the number of logging jobs has plummeted. That in turn has triggered a huge decline in student enrollment for Laona schools because of a drop in the Forest County population as people have had to move elsewhere in search of work.

It’s an intensely emotional issue, said Penzenstadler, adding that it’s hard to overstate the frustration of people in the logging and timber industry in northern Wisconsin.

They’re exasperated, disheartened and discouraged.

Their way of life is at stake. Their local school districts, businesses and economy are on the brink of collapse — and it does not have to be this way.

Millions of board feet of wood could be taken out of the Chequamegon-Nicolet while still preserving important portions of the forest.

The author says it merits “statewide attention.” I would think that the situation in the Lake States and the west merits national attention. If someone finds a story, please post in a comment. Required: in national news media, looks at situation nationally.

UPDATE: Looks like the entire series, which includes articles and video, is now available on-line. -mk

Colorado Forest Products (TM) PSAs

Found these PSAs for Colorado Forest Products (TM) in my email this afternoon.

The Colorado State Forest Service is very excited to announce that next week our first series of public service announcements (PSAs) featuring our Colorado Forest Products™ program will begin airing on the networks of 9News (KUSA, KTVD).

The creative process involved with the production of these appealing and informative 15 to 30 second PSAs has been both challenging and rewarding for the Colorado State Forest Service’s Wood Utilization and Marketing team. Please, take the time to view our 3 PSAs here:

Interesting that Andy had just posted below about “worthless” trees in 4FRI.. wonder what makes 4FRI’s “worthless” when some of the same kinds and sizes of trees are worth something in Colorado?

Here’s more stuff from the CSU website here:

Colorado’s Source of Wood Products

Colorado uses tremendous amounts of wood products, but it depends on imports from other states and countries to meet its needs. Key states exporting wood products to Colorado include Oregon, Idaho, Washington, California, Montana, Arkansas, Minnesota and Washington. Canada and Mexico also export large quantities of wood products into Colorado as well.

Purchasing Local Wood ProductsThere are existing businesses in the state of Colorado that produce and supply locally derived wood products. Purchasing products that were grown, harvested and manufactured in the state:

Decreases Fossil Fuel Consumption and EmissionsIn many cases, wood products are being transported great distances to Colorado. This increases the amount fossil fuel used and burned to transport materials.

Retains Consumer Dollars in Colorado Economy

Purchasing local products, keeps consumer dollars in Colorado’s economy and does not flow to other states. It also keeps local people employed whether they are working directly for the company or supply materials to the company or goes to the local grocery store it stays within the community.

Increases Ability and Opportunity to Improve Colorado’s Forest Health Conditions

Supporting local products produced with Colorado wood can help reduce forest management and restoration treatment costs because the wood coming out of the forest has value. When products are generated as a result of these treatments, they generate revenue and create an opportunity to improve Colorado’s forest health.

Closure and Rehabilitation of Temporary Roads

Here is a view of a temporary road used in a fire salvage portion of a green timber sale, on the Sequoia National Forest. The McNally Fire burned over 100,000 acres. Since this location is so remote, worries about vehicular entry are minimal. At the time, the logger and I thought these rocks would be adequate to block the road. I don’t think so, today. This was a temporary road before the fire, and there were some hydrological issues with re-using it. Of course, after a wildfire, the water table is recharged and new springs have popped up. It was very important that we laid out the restrictions and mitigations of its use. This is the result.

This view looks back down the road. You can see the waterbars and slash spread in between them. Even if the road is compacted, the water never gets a chance to gain erosive power. I’d bet that the road could be re-used again, when needed. The original road design wasn’t perfect but, I think there are very few impacts from us using it.

Senators Seek to Level the Playing Field for Domestic Wood Products in USDA BioPreferred Program

From Senator Pryor’s site here.

WASHINGTON D.C. – U.S. Senators Mark Pryor (D-AR), Roy Blunt (R-MO), John Boozman (R-AR), Angus King (I-ME), Susan Collins (R-ME), Mike Crapo (R-ID), and Orrin Hatch (R-UT) today introduced the Forest Products Fairness Act, a bipartisan bill that provides new opportunities for American forestry producers by allowing their products to qualify for the U.S. Department of Agriculture’s BioPreferred Program.

The USDA BioPreferred Program was created to provide new markets for farm commodities and encourage consumers to purchase environmentally-friendly biobased products. Despite the sustainability of wood, pulp and paper products, the USDA has not designated these products as a USDA Certified Biobased Products. The Forest Products Fairness Act would allow domestic forestry products to be labeled as biobased so they could receive increased consumer attention as well as federal government procurement preference. This designation would also level the playing field between domestically-produced wood products and imported products such as Chinese bamboo, which is already eligible for the biobased label and used as a “green” alternative for hardwood flooring or lumber.

“From farms to mills to manufacturers, it’s evident that the forestry industry is vital to Arkansas’s economy,” Pryor said. “By allowing these home-grown companies to expand and compete on same playing field as their international counterparts, our bipartisan bill will build on their success and keep this industry growing.”

“Forestry is an important economic driver in rural Missouri and nationwide,” Blunt said. “I’m glad to support this bipartisan bill, which will help increase economic opportunities for job creators and help our forestry producers compete in a competitive global economy.”

“Many Arkansas jobs depend on our renewable forest resources and the forest products industry and we need to end the discrimination in federal policy against these American jobs,” Boozman said. “This commonsense bill will provide domestically produced forest products with the same label and treatment as imported biobased products.”

“Maine is one of the most forested states in the nation and our forest-based industry plays an instrumental role in the vitality of our state’s economy,” said King. “By finally labeling forest products as what they truly are – biobased products – this bipartisan, common-sense measure will level the playing field for Maine’s foresters and help them to continue thriving in the global economy.”

“From timber to paper and pulp, Maine’s vast forest land is a tremendous source of value for our state’s economy and way of life,” Collins said. “I strongly support this bill because it would help dramatically expand the market for our domestic forest products by rightfully creating a level playing field with other biobased and foreign products.”

“In today’s economic climate, it is vital that we ensure Idaho’s industries are not at a competitive disadvantage due to a misinterpretation of terms,” Crapo said. “Legislation like the Forest Products Fairness Act makes it easier for the forest industry to compete in the global market place and bring economic growth and jobs to Idaho.”

“This bill takes an important step toward creating a level playing field for American businesses trying to compete with their overseas competitors,” Hatch said. “It’s a cost-free way to increase the use and awareness of domestic forestry products in a way that’s good for the economy.”

The BioPreferred Program was originally created by the 2002 Farm Bill to increase the purchase and use of biobased products. Under the program, every federal agency is required to rank their preference of biobased products for purchasing decisions. To increase consumer recognition of biobased products, the program also created voluntary labeling. Since the program’s inception, the USDA has designated more 33 items, representing nearly 3,000 products, as biobased products.

Bark Up or Down? Firewood Splits Norwegians

Here’s the link and below is an excerpt.

We received about 60 text messages from people complaining about the stacking in the program,” said Lars Mytting, whose best-selling book “Solid Wood: All About Chopping, Drying and Stacking Wood — and the Soul of Wood-Burning” inspired the broadcast. “Fifty percent complained that the bark was facing up, and the rest complained that the bark was facing down.”

He explained, “One thing that really divides Norway is bark.”

One thing that does not divide Norway, apparently, is its love of discussing Norwegian wood. Nearly a million people, or 20 percent of the population, tuned in at some point to the program, which was shown on the state broadcaster, NRK.

In a country where 1.2 million households have fireplaces or wood stoves, said Rune Moeklebust, NRK’s head of programs in the west coast city of Bergen, the subject naturally lends itself to television.

“My first thought was, ‘Well, why not make a TV series about firewood?’” Mr. Moeklebust said in an interview. “And that eventually cut down to a 12-hour show, with four hours of ordinary produced television, and then eight hours of showing a fireplace live.”